What is the Real Impact of Warehouse Packing Errors on Business Growth?

You pour everything into your product. You spend months refining the design, sourcing the best materials, and crafting a brand message that speaks to the hearts of your customers. You build a website that converts and a support team that cares. Finally, the order comes in. It is a moment of validation. But then, the last mile of that journey happens in the warehouse. And if the wrong item goes into that box, all your hard work unravels in seconds.

This is the nightmare that keeps passionate business owners awake at night. It is not just about the cost of return shipping or the inventory discrepancy. It is the moment your customer opens the box, full of anticipation, only to find confusion and disappointment. That moment breaks trust.

We know you care deeply about your team and your business. You want to build something that lasts. Yet, as you scale, the chaos of the warehouse floor can feel overwhelming. You are not looking for shortcuts. You are looking for a way to ensure that the vision you have for your company is executed perfectly, right down to the tape sealing the cardboard box.

The ripple effect of a mispack

When we talk about warehouse packers and shipping errors, we often look at the immediate financial loss. You have to pay for the return label. You have to pay to ship the correct item. You might lose the inventory if the wrong item is not returned or is damaged.

However, for a business owner who wants to build a remarkable brand, the damage goes deeper. A wrong item shipped equals lost money, but it also equals a tarnished reputation. In the age of social media, one unboxing disaster can reach thousands of potential customers.

Consider the operational drag as well. Your customer service team, which should be focused on helping customers succeed, is now bogged down in damage control. Your inventory count becomes unreliable, leading to ghost stock and forecasting errors. This creates a friction that slows down your entire organization.

Understanding the cognitive load on packers

To solve this, we have to look at the human element. Your warehouse staff are not robots. They are people working in a high-repetition, often high-stress environment. They want to do a good job, but fatigue and cognitive overload are real challenges.

In many warehouses, products look incredibly similar. A size medium looks just like a size large. A phone case for one model looks nearly identical to the case for the next generation. When a packer is moving fast to hit quotas, their brain can slip into autopilot. This is where mistakes happen.

Traditional training often involves handing a new hire a manual or showing them the layout once. We assume that because they saw it, they learned it. But in a chaotic environment where teams are growing fast or moving to new markets, simple exposure to information is not enough.

What is a Packing Loop?

This is where we move from basic instruction to a more robust concept known as the Packing Loop. This is a specific approach to learning and execution designed to break the autopilot mode and ensure accuracy.

A Packing Loop is not just a checklist. It is an iterative method of learning that quizzes workers on the most common look-alike items to prevent mix-ups. Instead of merely telling a packer to be careful, the Packing Loop actively engages their critical thinking before the mistake occurs.

Imagine a scenario where a worker is about to pack a specific SKU. A Packing Loop approach would involve training that presents them with images of the two most commonly confused items and asks them to identify the correct one based on subtle differences. It forces the brain to stop, analyze, and confirm.

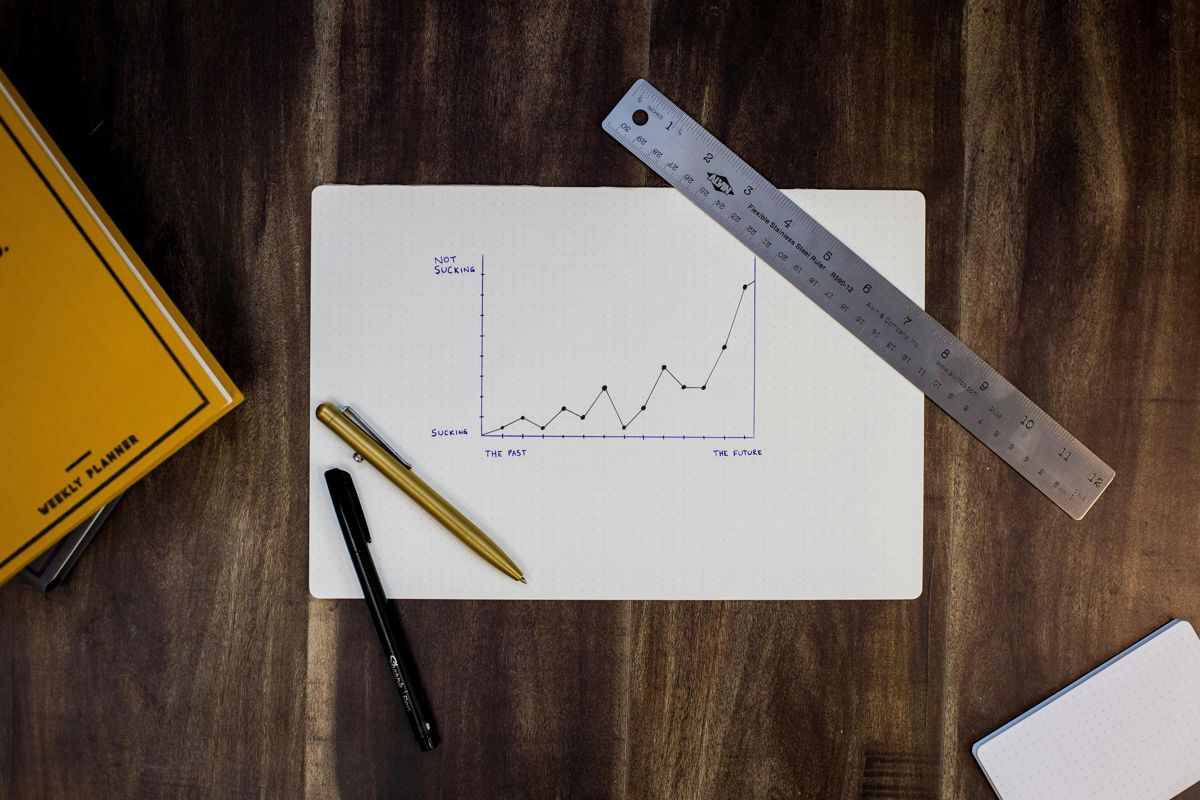

Comparing static training to iterative learning

Most businesses rely on static training. You tell the team what to do, and you hope they remember it three weeks later during a rush. But hope is not a strategy for a business that wants to be world changing.

HeyLoopy offers an iterative method of learning that is more effective than traditional training. It is not just a training program but a learning platform. In the context of the warehouse, this means the training does not end after onboarding. The Packing Loop continues to surface these critical distinctions, ensuring the knowledge is fresh.

Static training fades over time. Iterative learning builds muscle memory. For a packer, this means the distinction between Item A and Item B becomes second nature. They do not just guess; they know.

Why high growth teams need better systems

If you are reading this, you are likely in a phase of growth. You might be adding team members rapidly or expanding your product line. This introduces heavy chaos into your environment.

In these fast-moving scenarios, you do not have the luxury of long ramp-up times. You need your new hires to perform like veterans quickly. When teams are growing fast, the risk of tribal knowledge being lost is high. A Packing Loop system standardizes the knowledge so that accuracy does not depend on who is training whom.

This is particularly vital for teams that are customer facing, where mistakes cause mistrust and reputational damage in addition to lost revenue. The warehouse packer is the final guardian of your brand promise before it reaches the customer. They are, in a very real sense, a customer-facing role.

Managing risk in high stakes environments

For some business owners, the stakes are even higher. You might be shipping hazardous materials, expensive electronics, or medical supplies. These are teams that are in high risk environments where mistakes can cause serious damage or serious injury.

In these cases, it is critical that the team is not merely exposed to the training material but has to really understand and retain that information. A mispack here is not just an annoyance; it is a liability.

Using a platform that focuses on retention through quizzing and loops provides a layer of safety that manual checks cannot match. It ensures that the person handling the product understands the specific nuances required to handle it safely and correctly.

Building a culture of trust and accountability

Ultimately, implementing a strategy like the Packing Loop is about more than just metrics. It is about culture. You want to enable and empower your team to make your venture successful.

When a team member makes a mistake, they often feel terrible. If the environment is punitive, they hide mistakes. But if the environment is focused on learning and support, they grow.

HeyLoopy can be used to build a culture of trust and accountability. By giving your team the tools to master their roles, you are telling them that you value their contribution. You are investing in their competence.

Moving forward with confidence

You are building something remarkable. You are willing to put in the work and learn diverse topics to ensure your business thrives. Taking a scientific approach to warehouse accuracy—moving away from blaming individuals and toward improving the learning systems—is a hallmark of a mature, scalable business.

Look at your current shipping data. Identify the look-alike items that cause the most pain. Consider how you can implement a Packing Loop to quiz and reinforce the differences. It is a practical, straightforward step that reduces stress and helps you sleep better at night, knowing your customers are getting exactly what you promised them.