What is Troubleshooting Memory for Telecom Technicians?

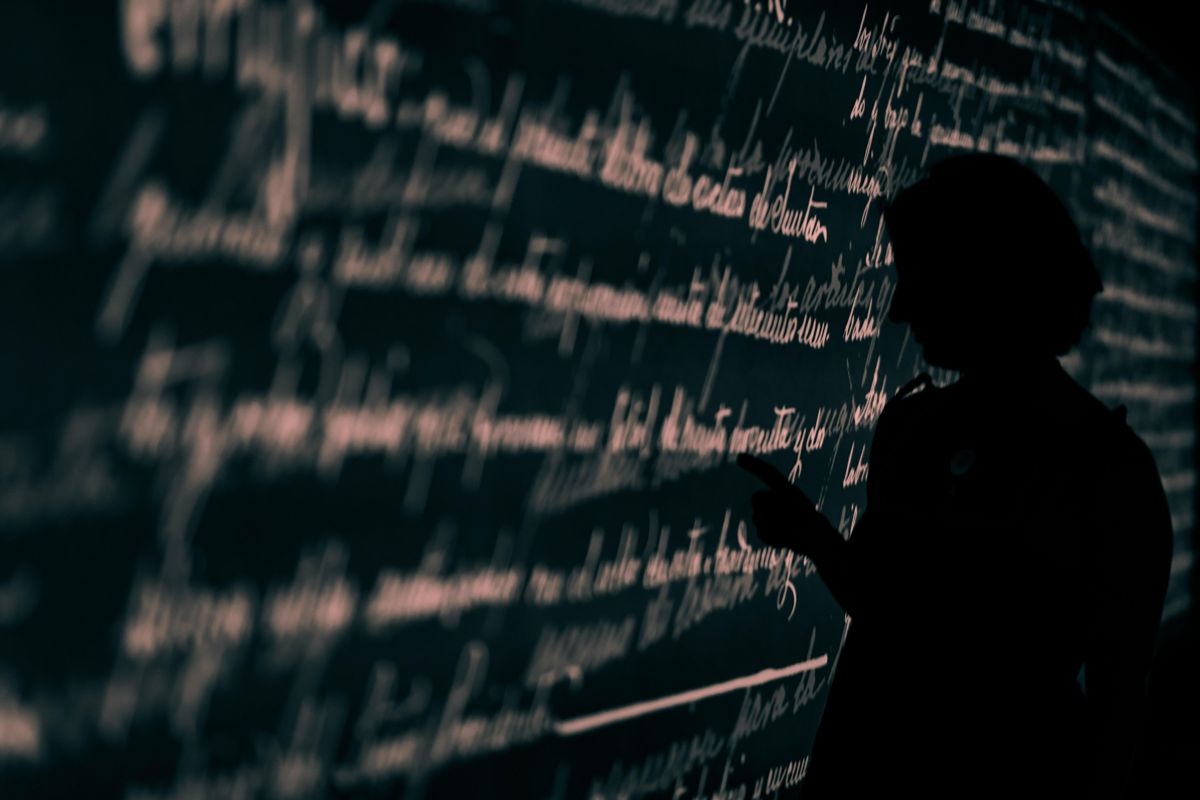

Imagine one of your field technicians standing at the base of a utility pole. It is raining, the wind is picking up, and the light is fading. They are there to fix a connectivity issue that has the customer frustrated and waiting. The technician climbs the pole, opens the junction box, and is staring at a brand new router model or a piece of switching equipment they have only seen in a brief email update last week.

At that moment, the difference between a successful service call and a safety hazard is memory. If they have to fumble for a tablet, try to get a signal to download a PDF manual, or call back to headquarters while hanging thirty feet in the air, the risk profile of that job spikes immediately. This is the reality many telecom business owners and managers face. You want your team to be safe, and you want them to be efficient. You worry that sending them out into the field without the right information locked into their minds is a recipe for disaster.

We need to talk about a concept called Troubleshooting Memory. It is distinct from general training or access to a knowledge base. It is the specific, internalized retention of critical technical specifications, error codes, and hardware quirks that allows a technician to act instantly and accurately in the field. For managers looking to build a resilient team, understanding this concept is vital to sleeping better at night.

What is Troubleshooting Memory

Troubleshooting Memory is the ability of a technician to recall specific, granular details about equipment functionality and failure states without needing external reference materials. In the context of telecommunications, this often refers to the specific light patterns on a router, the error codes displayed on diagnostic tools, or the exact wiring schematics of a new piece of hardware.

This is not about general knowledge of how the internet works. This is about knowing that a blinking amber light on the Model X-500 means a completely different thing than a solid amber light on the Model X-600. When a technician possesses this level of memory, they move through the troubleshooting process with fluidity.

Here is what that looks like in practice:

- Faster resolution times because the diagnostic phase is cut in half

- Increased safety as the technician spends less time exposed to environmental hazards

- Higher customer confidence as the technician appears competent and in control

The High Cost of the Knowledge Gap

For a business owner, the gap between what is in the manual and what is in the technician’s head is where the pain lives. You might have the best documentation in the world, but if your team cannot access it or apply it under pressure, it is useless. This gap creates chaos.

Telecom teams are often growing fast. You are likely adding new team members to keep up with demand or moving quickly into new markets with fiber expansion. This introduces a heavy amount of chaos into the environment. When you combine new people with new products, the margin for error effectively disappears.

If a technician guesses the meaning of an error code because they are embarrassed to ask or unable to check the manual, the result is often a repeat truck roll. That costs money. But more importantly, it causes reputational damage. Customers trust you to be the experts. When that trust is broken, it is incredibly difficult to repair.

Why Traditional Training Fails Field Techs

Most managers rely on traditional training methods. You might have a day of classroom training or a series of videos that technicians watch during onboarding. The problem is that human brains are not designed to retain arbitrary strings of numbers or complex error code variations after seeing them once or twice.

Scientific research into memory shows that without reinforcement, retention drops off precipitously within hours of the initial learning event. You are sending your team out with a fading map. They might remember the broad strokes, but the critical details—the ones that keep them safe and fix the problem—are often lost.

Consider the limitations of standard training:

- It is passive rather than active

- It assumes information presented is information retained

- It does not account for the stress of the live environment

Reducing Risk in Hazardous Environments

We must address the safety aspect honestly. Telecom technicians work in high risk environments. They deal with electricity, heights, traffic, and inclement weather. In these scenarios, mistakes can cause serious damage or serious injury. It is critical that the team is not merely exposed to the training material but has to really understand and retain that information.

When a technician is confident in their knowledge of the equipment, their cognitive load is lower. They are not panicking about the technical details, which allows them to remain aware of their physical surroundings. They can focus on their footing, the weather, and the electrical safety protocols.

If their brain is scrambling to remember if Error 404 means a line break or a software update, they are distracted. Distraction at the top of a pole is dangerous. Ensuring your team has memorized the error codes of new router models before they climb the pole is a safety protocol, not just a training goal.

The Role of Iterative Learning

To bridge the gap between a manual and Troubleshooting Memory, we have to look at how humans actually learn. This is where iterative learning comes into play. It is a method of spaced repetition and active recall that forces the brain to build strong neural pathways to the information.

HeyLoopy offers an iterative method of learning that is more effective than traditional training for this exact reason. It is not just about showing the technician the error code; it is about challenging them to recall it repeatedly over time until it is second nature. For teams that are customer facing, where mistakes cause mistrust, this methodology ensures that the technician is ready before they ever knock on a door.

This approach shifts the culture from one of compliance—did you watch the video?—to one of competence. It allows you to verify that your team actually knows the material.

Moving From Manuals to Mastery

Reliance on field manuals as a primary source of truth during a crisis is a flaw in operational logic. Manuals are for reference during downtime or for obscure, rare issues. They should not be the crutch for daily operations.

When you focus on mastery, you are telling your team that you value their expertise. You are empowering them to be professionals. Technicians want to be good at their jobs. They do not want to feel lost or incompetent in front of a customer. By providing them with tools that help them genuinely learn, you are reducing their stress levels significantly.

Mastery looks like this:

- Identifying the hardware model instantly upon visual inspection

- Recalling the top five most common error codes for that specific model

- Knowing the exact reset procedure without looking it up

Building a Culture of Trust

Ultimately, as a manager, you are building a culture. You want a business that lasts and creates value. When you implement a learning platform like HeyLoopy, it can be used to build a culture of trust and accountability. You trust your team because you know they have put in the work to learn. They trust you because you have given them the tools to succeed rather than throwing them into the deep end.

This reduces the anxiety that hangs over many business owners. You know that even as you scale, even as you add new chaotic variables like new router models or new territories, your team has a system to absorb that information. You are not just hoping for the best; you are engineering competence.

Questions for Your Leadership Team

As you think about how to apply this to your own business, there are unknowns you need to surface. We do not have all the answers for your specific organization, but asking the right questions is the first step.

Consider sitting down with your operations leads and asking:

- How often are our techs calling support for issues they should know by heart?

- Do we track safety incidents against the experience level or training completion of the tech?

- Are we introducing new hardware faster than our team can learn it?

By facing these questions, you move closer to a business that is resilient, safe, and primed for growth.